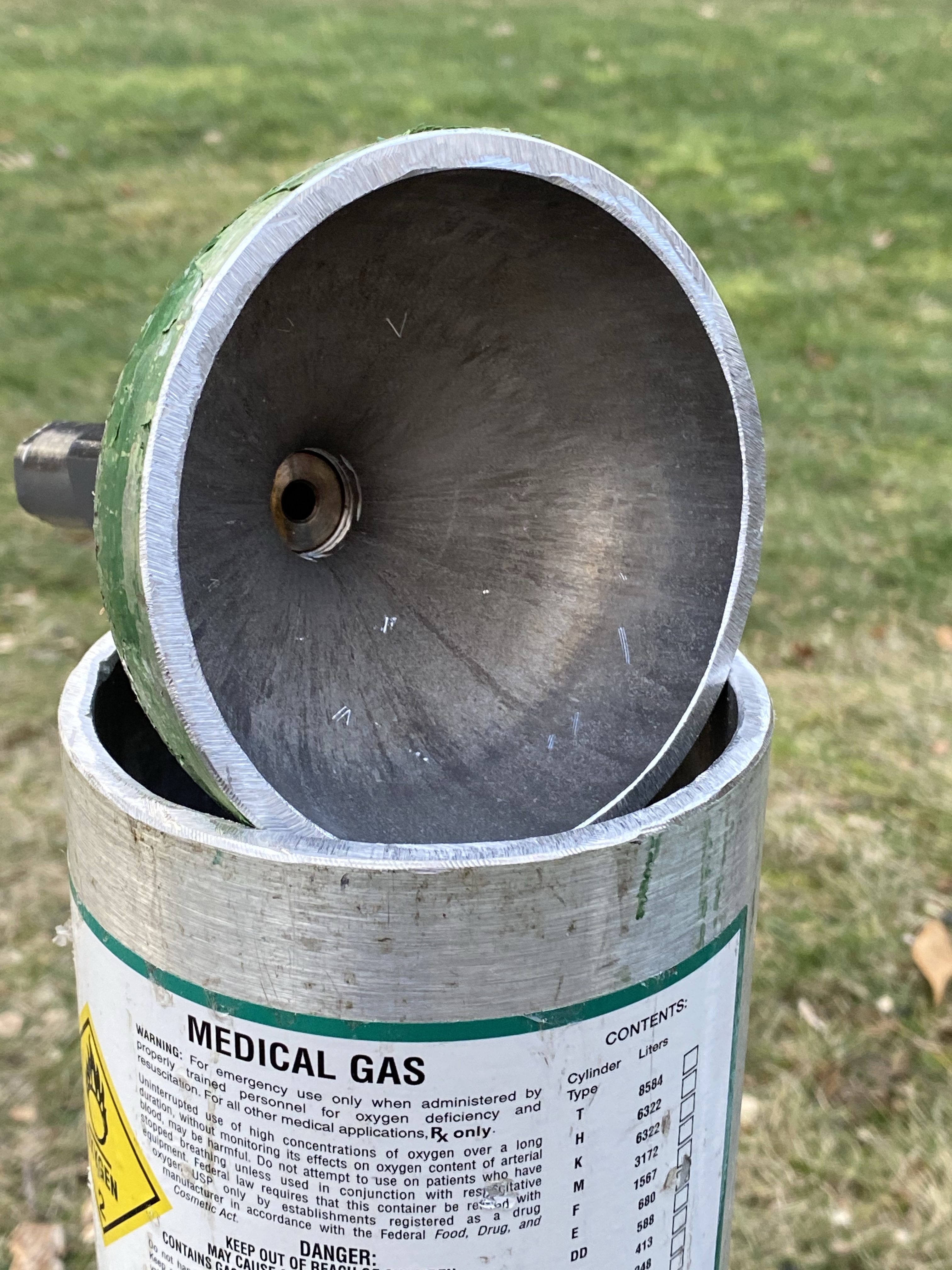

More often than not I’ll think of something that I need for Patch Hill Forge and lo, it appears on my next trip to the transfer station. This week I was lamenting my lack of a deep quench tank (the saucepan I stole from the kitchen was no where near deep enough) and look what I found in the metal bin. I bled it, very carefully removed the valve just in case it was still holding back pressure, filled it with water to make sure all of oxygen was gone, then chopped off the top. Very happy with my dumpster deity.

Blog

Lots of progress

I’ll just leave the gallery below that shows what I’ve been working on in the forge/workshop since the beginning of the year..

Patch Hill Forge, now not just in name

Funny how life gets in the way, or at least it’s easy to make that excuse. Just over two years since buying my anvil, I have a working blacksmith setup.

First up, an anvil stand. I chose 4x4s instead of a stump as I wanted it flat enough to put wheels on as my ‘shop’ is just my driveway, and to be able to add tool holders easily. I flame finished it (Shou Sugi Ban) to help protect it and hide the inevitable scorch marks.

Next, an anvil stand with a cutoff beam section from the Coolidge’s old barn and a Land Rover brake rotor from the dump. Post vises are hard to come by and are expensive, so this will do.

With some new tongs from blanks purchased from Ken’s Custom Iron, I’m in business.

More ‘raw’ materials

I’ve picked up some interesting oddities of late that I’ll take some pictures of, but the non-exhaustive list includes a huge 45-degree steel pipe flange that would make an interesting light, an ancient projector, two large wood pulleys, a beautiful very well-worn cobbler’s bench (from the Coolidge family; yes, that Coolidge) that could make a fantastic Edison chandelier, an oxen yoke (also Coolidge), hay forks, and even a lid to an in-ground kitchen scraps container.

I’ve been milling a little as well. I replaced the very out-of-place 2″ by 6″ pine mantel in my dining room with a 4″ thick piece of spalted birch. It may hold a world-record (well, maybe town-record) for shortest distance moved for a finished work; the birch stood less than 30′ from my fireplace. I’ve also milled some Eastern Cedar; it has the most amazing purple heartwood. Finally, I’ve squared (very roughly) a maple stump. You can see the picture below with latex paint on the end-grain to limit cracking during the drying process. They say it takes a year per inch of wood; I don’t think I have the patience to wait 9 years for this to dry…

Anvil and new pieces

I picked up an anvil just recently – they tend to be very expensive so when one comes up a little cheaper, you have to jump on it. Mine has a broken heel and horn, but still usable. I also added new items for sale – Kodak Photographic Safelights – these work really well with smart bulbs to wash a wall or fireplace with color. Coincidentally I also found parts of an old Graflex photo enlarger (pictured above as a WIP) that I’m repurposing – stay tuned for that.

And my lathe!

I also picked up a lathe from a town over – a 1953 fully working, 5′ bed metal lathe that I hope to also turn wood on. It will be well taken care of..

Apologies for the picture of it in the temporary home.

A forge…

Sooner than expected, I found myself a coal fired forge. A farrier had built it and the family was looking to sell it after he passed away; I’m pleased to be able to continue its use. I wasn’t planning on using coal – I was going to make a small propane forge, but this feels more traditional. Both blowers work nicely, just need a building to put it in..

Milling

Just a few pictures showing my milling setup: the Granberg Chain Saw Mill with a ripping chain – It works well, albeit a slow process. From my property, I’ve milled white birch (topped in the ice storm of Halloween 2011), red oak (the root ball would move in strong winds), and ash (none of the ash trees are doing well around here).

What’s in a name?

Patch Hill Forge? The location, Patch Hill is simple. I live on the side of a steep drumlin carved out over 11,000 years ago when the ice above my head would have been a mile and a half thick.

Patch Hill Forge? The location, Patch Hill is simple. I live on the side of a steep drumlin carved out over 11,000 years ago when the ice above my head would have been a mile and a half thick.

The piece of land that the hill is on was named sometime prior to 1798, where it’s shown on a map next to property owned by Isaac Patch. The hill was called “Pine Tree Hill”- but that’s been lost to time (as have the pines), and it’s simply called Patch Hill now.

How about “Forge”? This is a long-term vision, and that vision includes a forge, I’m a long way off that, both in terms of building a actual forge, and being proficient to sell items I smith. I’ll get there eventually.

Welcome to Patch Hill Forge

I hope this is the start of something really enjoyable. Making unique items for my home has been a passion for many years – I want to share that passion with others. Furthermore, I want to help preserve items from the past, giving them a new lease on life.

This website will be both a catalog of items already sold (and which may provide inspiration for bespoke items for your home), and items for sale that a smaller in nature, or I had a very specific idea for.

Please don’t hesitate to contact me with questions you may have, or to discuss the creation of a piece.